Why is SOI extremely popular in RF chip applications?

Small parasitic capacitance; high integration density; fast speed

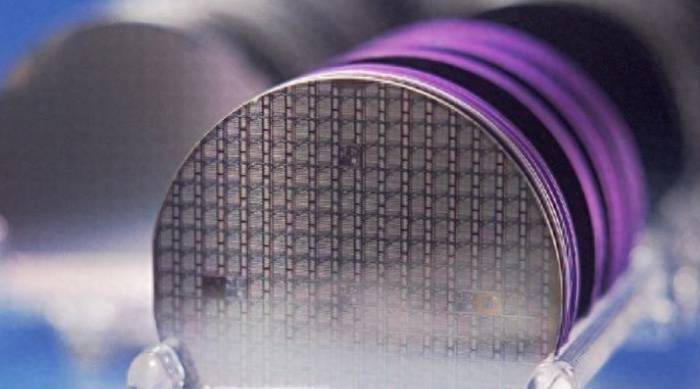

What is SOI?

SOI, which stands for Silicon-On-Insulator, refers to silicon on an insulating substrate. This technology introduces a buried oxide layer between the top silicon layer and the back substrate. The principle is to insert an insulating material between silicon transistors, which can reduce the parasitic capacitance between them by half compared to the original. There are three types of technologies for forming SOI materials:

1. Separation by Implanted Oxygen (SIMOX)

2. Bond and Etch-back SOI (BESOI)

3. Smart-Cut

Advantages of SOI

SOI materials possess advantages that bulk silicon cannot match: they can achieve dielectric isolation of components in integrated circuits, completely eliminating the parasitic latch-up effect in bulk silicon CMOS circuits. Integrated circuits made from this material also have the advantages of small parasitic capacitance, high integration density, fast speed, simple process, small short-channel effects, and are particularly suitable for low voltage and low power circuits.In addition, the impedance value of the substrate itself in the SOI wafer also affects the performance of the components. Therefore, some companies have later adjusted the impedance value on the substrate to improve the characteristics of the radio frequency components (Radio Frequency Component, RF Component). Some of the electrons that should pass through the switch will penetrate into the silicon, causing waste; SOI can prevent the loss of electrons and compensate for some of the shortcomings of the CMOS components in the original Bulk wafer.

Advertisement

RF SOI is a silicon-based semiconductor process material with a unique three-layer structure of silicon/insulating layer/silicon, which achieves full dielectric isolation between the device and the substrate through the insulating buried layer (usually SiO2). Because RF-SOI can achieve higher linearity and lower insertion loss at the best cost-performance ratio, it can bring people faster data speeds, longer battery life, and more stable and smooth communication quality with more stable frequencies.

For decades, the telecommunications infrastructure market has been driven by macro and micro base stations. Now, with the help of 5G large-scale MIMO active antenna systems, the RF component industry is choosing more and more RF components. Yole Intelligence, a subsidiary of Yole Group, estimates that the telecommunications infrastructure RF market was worth $3 billion in 2021 and is expected to reach $4.5 billion by 2025.

The three major development directions of SOI are:

RF-SOI: It is a silicon-based semiconductor process material with a unique three-layer structure of silicon/insulating layer/silicon, which achieves full dielectric isolation between the device and the substrate through the insulating buried layer (usually SiO2). Because RF-SOI can achieve higher linearity and lower insertion loss at the best cost-performance ratio, it can bring people faster data speeds, longer battery life, and more stable and smooth communication quality with more stable frequencies. RF-SOI can ensure very high signal linearity and signal integrity.

Power-SOI: The main structure consists of a single-crystal top silicon layer, an intermediate buried oxide layer, and a silicon base at the bottom. Due to the thickened Buried Oxide structure of Power-SOI wafers, it can effectively overcome the problem of high voltage penetrating components, achieving stability in the use of power components. Therefore, Power-SOI is mainly used in the integration of high-voltage components in BCD (BIPOLAR-CMOS-DMOS) power integrated circuit manufacturing technology.

FD-SOI: (Fully Depleted Insulated Gate on Silicon) is a planar process technology. From a structural point of view, the electrostatic characteristics of FD-SOI transistors are superior to traditional bulk silicon technology. The buried oxide layer can reduce the parasitic capacitance between the source and drain, and effectively suppress the flow of electrons from the source to the drain, thereby significantly reducing the leakage current that leads to performance degradation. In addition, FD-SOI also has many other unique advantages, including the ability to back-bias, excellent transistor matching characteristics, the ability to use low power supply voltages close to the threshold, ultra-low sensitivity to radiation, and very high intrinsic transistor operating speeds, which make it capable of working in millimeter wave frequency applications.

The application fields of SOI are:

RF-SOI is applied to RF applications and has become the best solution for switches and antenna tuners in smartphones;POWER-SOI for Smart Power Conversion Circuits, mainly used in automotive, industrial, consumer electronics and other high-reliability, high-performance scenarios;

FD-SOI has the advantage of reducing silicon geometric dimensions while simplifying the manufacturing process, mainly applied in the fields of smartphones, the Internet of Things, 5G, automotive, and other applications that require high reliability, high integration, low power consumption, and low cost; Optical SOI is applied in the field of optical communication such as data centers and cloud computing.

Scope of RF-SOI Application

Chips using the RF SOI process are targeted at a variety of applications, but the largest market is the RF front-end module in mobile phones. RF SOI chips are not the only devices used in mobile phones. Smartphones consist of digital chips and RF chips, as well as power management chips. The CMOS-based digital part is composed of application processors and other devices.

RF components are integrated into the RF front-end module, which is responsible for handling transmission/reception functions. The front-end module consists of multiple components, including power amplifiers, antenna tuners, low-noise amplifiers (LNA), filters, and RF switches. The LNA is used to amplify the small signal from the antenna, while the filter prevents any unwanted signals from entering the system. The LNA and filters use different processes.

At the same time, switch chips and tuners are based on RF SOI. RF switches transmit signals from one component to another, and tuners help the antenna adjust to any frequency band.

Over time, 5G will also operate in the millimeter wave band. This involves frequency bands between 30 GHz and 300 GHz. The RF architecture needs to be modified to cover one of these bands. For this, the RF transceiver will combine the IF or intermediate frequency transceiver and the downconverter with a CMOS-based millimeter wave RF front-end module.

GF Millimeter Wave 5G Beamforming SystemThe Application of RF-SOI in Smartphones

Smartphones integrate a variety of functions, including radio transmission and reception, digital processing, storage, audio, battery management, photography, and display. Through the front-end module, they can achieve the transmission and reception of RF signals between mobile phones and base stations. The market demand for high-performance switches became more intense in 2016. At that time, LTE technology had evolved, leading to the emergence of 4G and many complex modules, as well as antenna tuners. RF-SOI was also applied to more and more antenna tuners and switches. For RF front-end switches and RF front-end control devices, RF-SOI is the most widely used.

In smartphones, RF switches are in a key position in the RF front end and are indispensable. Their performance, such as insertion loss, return loss, isolation, harmonic suppression, and power capacity, has an important impact on the RF front-end link. The main function of RF switches is to control the logic to switch signals in different directions (receive or transmit) and different frequencies, in order to share antennas and save the cost of terminal products.

Developing to today's 5G era, smartphones require more complex modules and higher integration. LNA is also integrated into the switch. 5G millimeter wave has a stronger demand for high integration. At present, nearly 100% of RF switches are based on Connect-SOI technology, that is, RF-SOI or FD-SOI technology; more than 80% of integrated low-noise amplifiers are developed based on RF-SOI, and nearly 100% of antenna tuners are using Soitec's SOI technology. It is said that Soitec's RF-SOI products have become industry standards, and are used in large-scale production to manufacture ICs for RF front-end modules, while meeting the cost and performance requirements of chip manufacturers.

The Application of RF-SOI in the Automotive Field

Compared with smartphones, modern cars have a higher demand and dependence on connectivity. Current remote communication not only uses cellular networks but also relies heavily on V2X connections, and also uses dedicated short-range communication systems, including WiFi, Bluetooth, etc. Emerging 5G, Wi-Fi 6(E), and V2X, as well as other connection systems, are helping to further expand the scope of mobile services. For example, they improve driving safety by enhancing wireless interaction between vehicles and road infrastructure, or optimize traffic conditions by wireless interaction between other vehicles. In-vehicle wireless connections can also easily access high-quality video and audio entertainment content in the car, making passengers more comfortable.

RF-SOI can not only be applied to smartphones, but also can be seen in many daily life devices. RF-SOI is also used in the Internet of Things devices used every day, such as smart earphones, watches, etc. It is not only suitable for cellular communication but also includes 5G, Bluetooth, WiFi, and ultra-wideband UWB. For millimeter wave, there are also similar challenges in improving integration. For millimeter wave, customers can choose different RF front-end architectures according to the final application. Some customers may prioritize very high-performance RF front ends, while others may sacrifice some performance to obtain higher integration and smaller chip sizes. For the first case, a complete high-performance RF front end (PA + LNA + switch + phase shifter + support function) can be integrated into RF-SOI; for the second case, part of the frequency conversion and RFFE can be integrated into FD-SOI technology. This ultimately depends on the customer's application and their competitive strategy.

If you have any requirements for tape-out, please scan the code to contact us.

Tower RF-SOI PlatformTower Semiconductor's RF-SOI and RF-CMOS technology solutions can provide high-speed, low-noise, and low-power products for consumer, infrastructure, and automotive applications.

Tower Semiconductor's RF SOI platform features a low Ron-Coff (on-resistance-off-capacitance), high linearity, and a feature-rich platform that enables the highest performance 4G/LTE and 5G front-end module (FEM) products. Tower Semiconductor's RF-SOI process series combines 3-7 metal layer CMOS processes along with 1.2V, 1.8V, 2.5V, and 5V transistor options. Based on silicon-verified accurate models and design libraries, as well as world-class design support and extensive mass production experience, it provides customers with the perfect RF solutions. Such processes are highly suitable for products that require isolation, such as cellular switches, achieving excellent channel isolation of better than >-40dB, insertion loss of less than 0.35 dB, low harmonics better than 110dBc at cellular power levels, and intermodulation distortion of less than -117 dBm. Low noise amplifiers can also be integrated with specific low noise, high gain devices, high linearity, and low loss inductors achieved through thick copper or aluminum layers. In addition to active devices, process options also include silicided and non-silicided poly resistors, RF metal-insulator-metal (MIM) capacitors, metal fringe capacitors (MFC), scalable geometric inductors, fixed geometric inductors, fixed geometric baluns (balanced-unbalanced transformers), and transformers. Substrate options include a "thin film" process with the best Ron-Coff performance and a "thick film" process similar to the behavior of active MOSFET gate electrodes, without floating body effects. The platform is supported by our MPW program for rapid project development.

RF-SOI Platform Features:

- 200mm and 300mm process technologies with high-resistivity SOI substrates

- Sub-60fs Ron-Coff 2.5V NMOS

- Dedicated devices for LNA integration

- High-density (4IF/µm²) and high-voltage (> 25V) MIM capacitors; high linearity metal fringe capacitors

- Low and high-value resistors, RF varactors, high-Q inductors

- High impedance, high linearity SOI substrates

- BSIM4 SOI PSP, HiSIM SOI modelsAluminum or Copper Low-RC Metalization Process

Support for 1.2, 1.8V, 2.5, 3.3 or 5V MOSFETs

High Utilization Standard Cell Library

For Reducing Switching Stacks

High-Precision RF Device Models and Rapid Parasitic Parameter Extraction

Advanced Substrate Modeling

Market Sectors Served by RF-SOI

Tower Semiconductor

Tower Semiconductor Ltd. (NASDAQ: TSEM, TASE: TSEM), a global leader in specialized process wafer foundry, operates the Tower Semiconductor brand in collaboration with Jazz Semiconductor, Inc. and TowerJazz Texas Inc., as well as TowerJazz Panasonic Semiconductor Co.Tower Semiconductor's clientele spans across various sectors such as automotive, medical, industrial, consumer, aerospace, and defense. Over the past few years, while propelling the success of its customers, Tower Semiconductor has achieved record-breaking growth in performance. We will continue to pursue excellence in technology and quality to maintain a robust growth outlook.

About Moore Elite

Moore Elite is dedicated to the mission of "making chip development in China easy," providing a one-stop chip design and supply chain platform. By integrating its own packaging and testing factory and equipment with rapid response capabilities, Moore Elite offers a long-term, large-scale, standardized, secure, and efficient "one-stop delivery from chip development to mass production" solution for chip and end-product companies with diverse and customized chip needs. This approach reduces customer risks, accelerates product market entry, enhances operational efficiency, and helps customers address the bottleneck issues in China's chip industry.

Founded in 2015, the core team of the company comes from companies such as IBM, SMIC, and ASE, with rich experience and capabilities in supply chain management. The business covers 800 chip customers, with a layout of 20,000 square meters of packaging and testing factories in Wuxi, Hefei, and Chongqing, and core equipment investment exceeding 400 million yuan.

Post a comment